The ultimate guide to warehouse labels: Organise your inventory and boost productivity

Revolutionise your warehouse operations with highly efficient warehouse labels

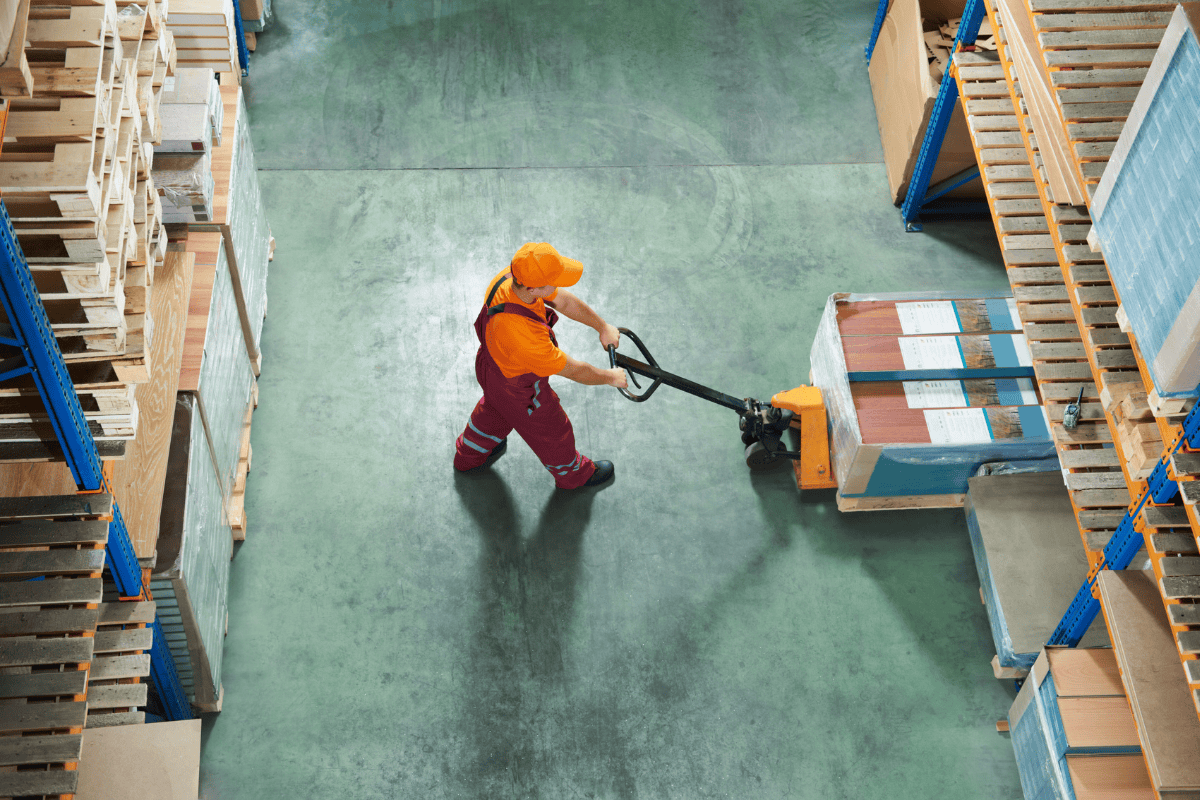

Efficient inventory management is the key to the success of any warehouse. A well-organised warehouse with proper labelling can help reduce errors, increase productivity, and improve picking accuracy. Implementing a warehouse labelling system can significantly impact warehouse efficiency, save time, and enhance the overall customer experience.

In this blog post, we will explore the benefits of implementing a warehouse labelling system to help warehouse and inventory managers create a more efficient and productive work environment.

What is warehouse labelling and why is it important?

Warehouse labelling is the process of assigning labels to various products, shelves, racks, bins, and other areas of a warehouse. It helps warehouse and inventory managers organise their inventory, making it easier for employees to locate and pick products. A well-designed warehouse labelling system can help track inventory, improve picking accuracy, streamline warehouse operations, improve the supply chain, and create a more organised work environment.

Improved inventory management

A well-designed warehouse labelling system enables you to track inventory accurately and efficiently, minimising the risk of stockouts or overstocking. According to a study by Wasp Barcode Technologies, inventory accuracy increases by up to 27% with a barcode labelling system in place. By implementing a warehouse labelling system, you can quickly identify the products’ exact location, reduce time spent searching for them, and minimise the risk of misplaced or lost inventory.

Increased picking accuracy

A warehouse labelling system can improve picking accuracy, reducing the number of errors and improving productivity. A study by Zebra Technologies found that implementing barcode scanning reduced picking errors by 39%, from 3.5 errors per thousand to 2.1 errors per thousand. By implementing barcode labels, warehouse employees can scan the products and instantly identify the exact location, reducing errors and improving picking accuracy.

Efficient warehouse operations

A well-designed warehouse labelling system streamlines operations by reducing the time spent on searching for products or supplies. According to a study by ID Label, implementing rack and location labels can reduce the time spent on finding products by up to 50%. By organising inventory through bin location labels, rack labels, and floor labels, warehouse employees can quickly locate products, reducing time spent searching, and increasing productivity.

Improved supply chain

A warehouse labelling system helps to improve the supply chain by enabling accurate tracking of products and supplies. A study by the Council of Supply Chain Management Professionals found that implementing a warehouse labelling system can reduce lead time by up to 23%. By implementing barcode labels and asset tracking, warehouse managers can quickly identify the products’ exact location and track them throughout the supply chain.

Better warehouse organisation

A well-designed warehouse labelling system can help to organise the warehouse, reducing clutter and creating a more efficient and productive work environment. According to a study by Honeywell, implementing a warehouse labelling system can increase productivity by up to 20%. By implementing bin location labels, rack labels, and floor labels, warehouse managers and inventory managers can create a more organised work environment, improving efficiency and productivity.

Warehouse signage and safety

Proper warehouse signage and safety are crucial for a well-designed warehouse labelling system. By implementing clear and concise warehouse signage, warehouse employees can quickly identify the products’ exact location and reduce the risk of accidents. Warehouse labelling can help improve warehouse safety by organising inventory and reducing clutter.

For Example popular floor markings are:

- Hazard Markings

- Loading/Unloading Zones

- Staging Areas

- Storage Areas

- Safety Signs

- Warehouse Forklift Hazard

Key benefits

Implementing a well-designed warehouse labelling system can have a significant impact on warehouse organisation, inventory management, supply chain, and overall productivity. By accurately tracking inventory, improving picking accuracy, streamlining operations, and creating a more efficient work environment, warehouse labels can help businesses of all sizes save time and money, while also enhancing customer satisfaction. Remember, the benefits of warehouse labels go beyond just the tangible improvements in efficiency and productivity. By investing in a warehouse labelling system, you’re also investing in your employees’ safety, as labels help prevent accidents and injuries. At the end of the day, implementing a warehouse labelling system is a smart investment for any business looking to improve their warehouse operations and take their business to the next level.

Not sure where to start?

Our team are experts in choosing suitable warehouse labels and warehouse labelling systems for your specific application and environment. We are happy to advise and recommend the most efficient and cost-effective solution for your workplace.