Understanding the Importance of Electrical Safety in Wind Farms

Wind farms are a crucial part of the UK’s renewable energy sector, which has expanded to account for 42.2% of the nation’s energy supply in 2024. Of this, wind farms contribute 29.5%, underscoring their growing role in the UK’s clean energy future. As the industry grows, so does the need for robust electrical safety measures. Wind turbines generate high voltages and operate in remote environments, which significantly increases the electrical risks associated with them. It is essential to implement safety measures to reduce these risks and protect the workers who maintain them.

Key Electrical Safety Risks in Wind Farms

Wind turbine electrical systems involve high-voltage components and critical connections. Proper safety protocols are crucial to prevent severe accidents such as electrical shocks, fires, and fatalities. The following are some of the main risks:

Arc Flash Hazards

Arc flashes occur when electrical current passes through air between uninsulated conductors, creating dangerous flashes of light and extreme heat. These hazards need to be mitigated with effective safety protocols.

Electrocution

The high-voltage electrical systems of wind turbines present a serious risk of electrocution, especially when maintenance work is conducted without ensuring that electrical systems are properly de-energised.

Electrical Fires

Faulty wiring or malfunctioning components can trigger electrical fires, putting workers and equipment at risk.

Lightning Strikes

Wind turbines, particularly those located in open fields or offshore, are highly susceptible to lightning, which can cause electrical surges and damage to equipment.

Implementing Key Electrical Safety Protocols

To mitigate these electrical risks, it’s vital to adhere to established safety standards, which help safeguard workers and prevent costly damage to equipment.

Lockout/Tagout (LOTO) Procedures

Lockout/tagout (LOTO) procedures ensure that electrical systems are isolated before maintenance work begins, reducing the risk of accidental activation. Under the Electricity at Work Regulations 1989, adhering to these procedures is legally required.

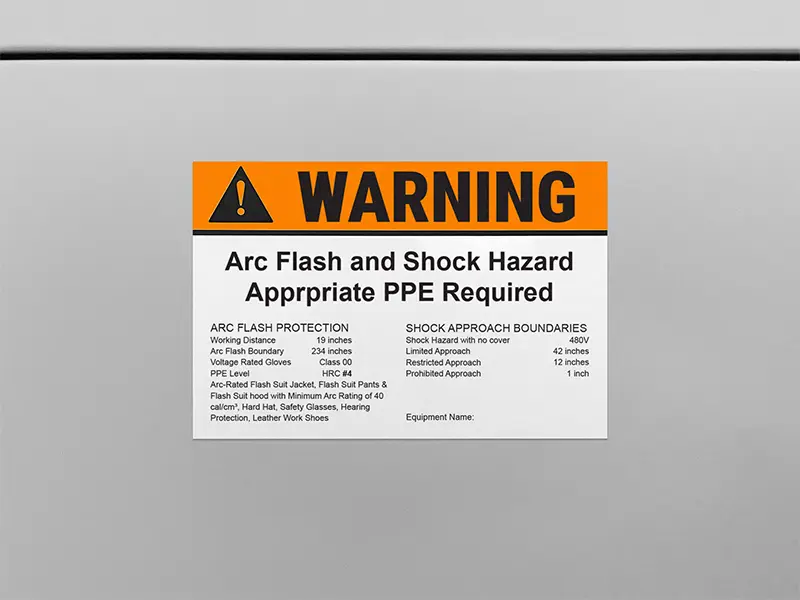

Arc Flash Safety Measures

Arc flash incidents are severe but preventable. Operators must label electrical panels and equipment with appropriate warning signs that highlight the risks and outline the required PPE and emergency procedures.

Regular Electrical Inspections

Routine inspections, as mandated by the Health and Safety at Work Act 1974 and Electricity at Work Regulations 1989, are essential for detecting potential faults and ensuring that electrical systems comply with safety standards.

Protecting Workers with PPE and Training

Proper Personal Protective Equipment (PPE) is critical for preventing electrical injuries. Workers should use the following equipment when working with live electrical components:

- Insulated Gloves: Essential for working with live electrical components to prevent electrical shocks.

- Flame-Resistant Clothing: Protects workers from severe burns in the event of an arc flash.

- Face Shields and Eye Protection: Safeguard against flying debris and arc flash burns.

Additionally, comprehensive training in electrical hazard awareness and emergency response is vital for ensuring that workers adhere to safety protocols.

Remote and Offshore Wind Farms

Offshore and remote wind farms present unique safety challenges due to limited access to medical help and harsh environmental conditions. Adhering to safety protocols and ensuring effective communication and remote monitoring are key to maintaining electrical safety in these environments.

Strengthening Electrical Safety in Wind Farms

Adhering to electrical safety best practices is crucial to minimise accidents and protect both workers and equipment. Implementing lockout/tagout procedures, using arc flash safety labels, ensuring proper PPE, and conducting regular inspections will strengthen safety protocols across wind farm operations.

To support these critical practices, Certags offers a range of solutions, including LOTO tags and arc flash labels, helping companies stay compliant and improve safety standards across the industry.

Wind Turbine Safety Made Simple – Get Your Free Guide Today

Ensure your team follows best practices with our Electrical Safety and Procedures Checklist for Wind Turbines. This free guide covers essential safety measures, including LOTO, arc flash precautions, and inspection protocols.