Inspection Made Simple with Customised Tags and Labels

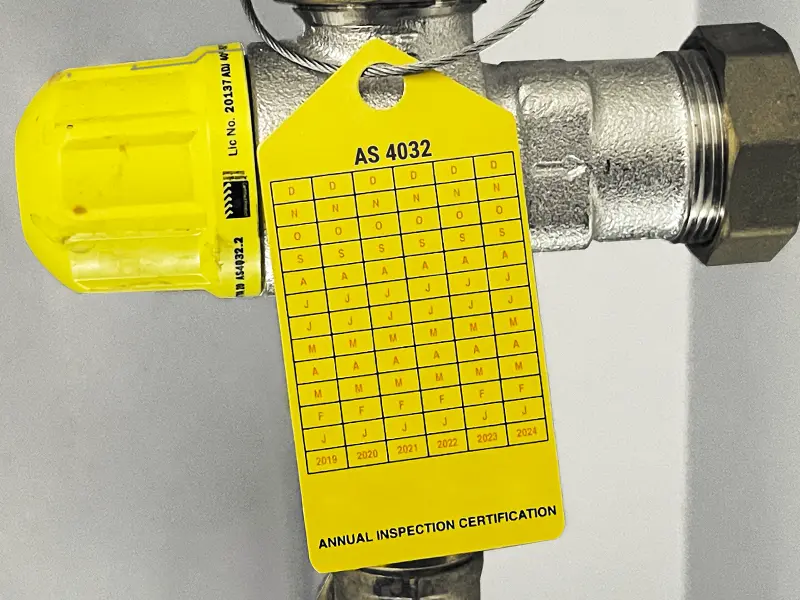

Our durable, customisable inspection tags and labels are designed to meet the demands of various applications, including equipment checks and asset tracking. Our products offer key benefits, including:

- Durable materials for long-lasting performance in tough environments while maintaining the readability of vital information.

- Customisation options with specific information, sizes, colours, and materials to perfectly suit your application needs.

- Compliance assurance with tags and labels tailored to industry standards.

- Versatility across a wide range of applications and industries.

Ensure compliance and proper usage by checking the inspection standards and protocols for your specific industry and application.