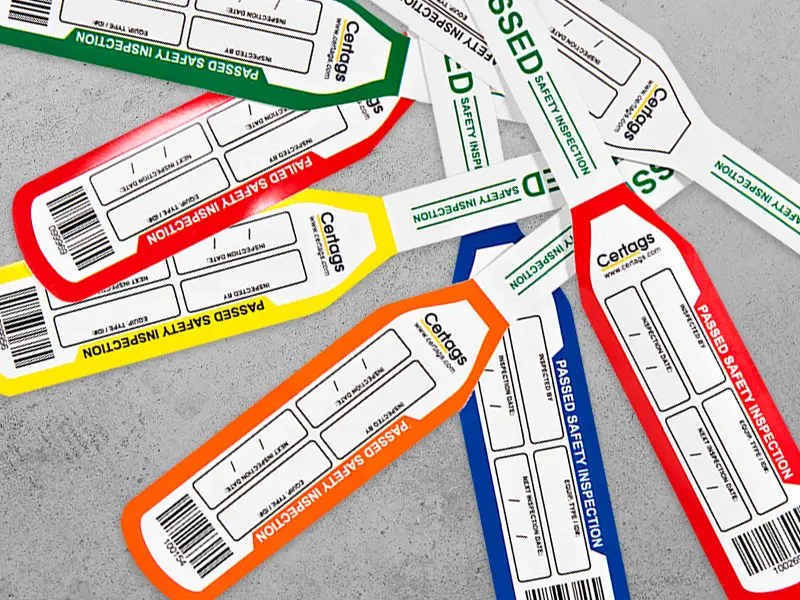

Bat Tags

Inspecting and Tracking Fall Protection Equipment

Bat Tags are made from heavy-duty PVC and are designed to be securely applied to equipment using adhesive and a nylon clip, ensuring compliance with safety regulations and keeping it in optimal working condition. Ideal as height safety equipment inspection tags and fall restraint tags.

Bat Tags typically contain critical information such as:

- Inspection date

- Inspector details

- Condition status

- Maintenance records

Do you have any questions? Get in touch with us and we will gladly answer any questions you might have.

Bat Tags come in various styles to suit different needs:

- Hand-writable Bat Tags are perfect for on-site, in the field recording of inspection details.

- Scannable codes, such as QR or barcodes, create an easy and convenient way to manage assets for sites with electronic record-keeping.

- Hole Punch Bat Tags are a great alternative to handwriting, as they offer a quick way to identify inspection information.

- Colour Coded Bat Tags are a classic way to quickly identify and classify equipment based on type, purpose, inspection period, etc.

We can print any industrial label to suit your needs.

Fast Turnaround

Quality Products

Attentive Service

Fill out the form below for a free sample pack of products and a chat about how we can help meet your business needs.

Market leaders in industrial labelling

Identify your industrial labels with custom branding and information of your choice, made with the highest quality materials.

- Durable labels that won’t peel at the edges

- Variety of custom options such as laminate flaps, perforations and holes

- Full colour printing

- Large choice of materials and configurations, guided by our expert staff

- Free complimentary artwork service with each product so your tags and labels come out just the way you want it.

Bat tags are used in various industries, including construction, rooftop work and rope access work to track the inspection and maintenance of fall protection and safety equipment.

1. Peel the backing from adhesive tail.

2. Wrap the tag around equipment and apply to itself.

3. Secure nylon clip to tag with pliers, ensuring both front and tail are locked in place