Understanding Different Barcode Types

Are you familiar with barcodes and their significance in today’s digital world? In this comprehensive article, we will explore the world of barcodes, their uses, benefits, and how they have revolutionised various industries. Whether you’re a business owner, a consumer, or simply curious about barcodes, this article will provide you with a deep understanding of this essential technology.

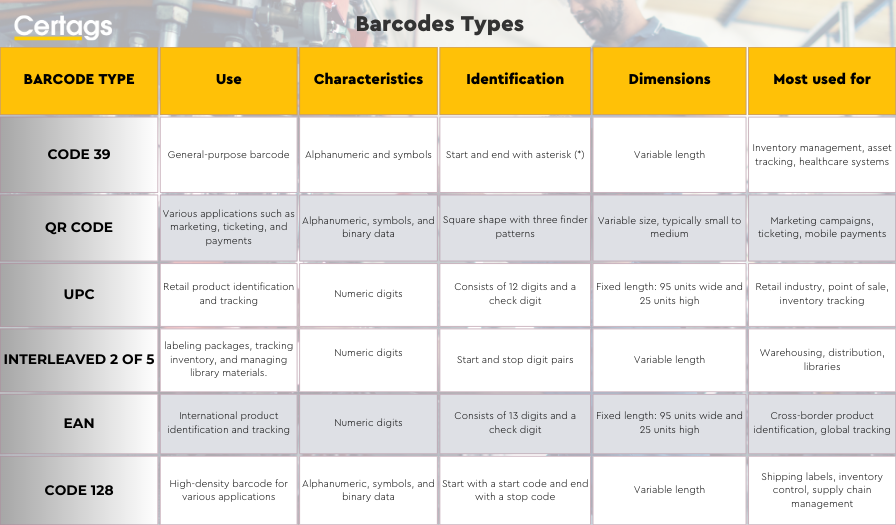

Code 39

Code 39 is one of the oldest and most widely used barcode symbologies in the industry. It is known for its versatility and widespread compatibility with barcode scanners. Code 39 can encode a variety of characters, including uppercase letters, numeric digits, and a set of special symbols. This barcode type is easily identifiable as it starts and ends with an asterisk (*).

Code 39 is self-checking, meaning it includes a check character that enhances the accuracy of data scanning. It finds extensive applications in inventory management, asset tracking, and healthcare systems. Due to its simplicity and reliability, Code 39 continues to be a popular choice for encoding alphanumeric data and facilitating efficient data capture and tracking processes.

QR Codes

QR codes short for Quick Response codes, have become increasingly popular in recent years. These square-shaped barcodes are designed to store and transmit information quickly and efficiently. QR codes can encode a wide range of data types, including URLs, text, contact information, product details, and more. One of the key advantages of QR codes is their ability to be easily scanned by smartphones and other mobile devices.

Users can simply point their device’s camera at a QR code, and with the help of a QR code scanning app or the device’s native camera app, they can quickly access the encoded information. This ease of use has made QR codes widely adopted in various applications, such as marketing campaigns, ticketing systems, mobile payments, product packaging, and even in everyday life for sharing information. With their versatility and convenience, QR codes have become a valuable tool for businesses and individuals alike, enabling seamless digital interactions and enhancing customer engagement.

UPC (Universal Product Code) Barcodes

One of the most widely recognised barcode types is the Universal Product Code (UPC). UPC barcodes are primarily used in retail environments to identify and track products. They consist of a series of vertical lines and numbers, which are scanned by barcode readers to retrieve product information from a database.

A typical UPC barcode includes a 12-digit numerical code, divided into three sections: the manufacturer’s identification number, the product number, and a check digit for error detection. These barcodes are commonly found on consumer goods, allowing retailers to manage inventory efficiently and process transactions accurately.

Interleaved 2 of 5

Interleaved 2 of 5 is a numeric barcode symbology that is widely used in various industries. It is known for its high-density format and efficient representation of numeric data. Interleaved 2 of 5 gets its name from the encoding process where it interleaves two digits together. This barcode type is commonly utilised in applications such as warehousing, distribution, and libraries. It is particularly effective for labelling packages, tracking inventory, and managing library materials. Interleaved 2 of 5 barcodes consist of start and stop digit pairs, allowing for variable-length encoding. With its ability to encode numeric digits and its high data density, Interleaved 2 of 5 provides an effective solution for businesses and organisations requiring precise and compact barcode representation.

EAN (European Article Number) Barcodes

The European Article Number (EAN) barcode is widely used in Europe and other parts of the world. Similar to the UPC barcode, EAN barcodes also contain a 13-digit numerical code. The first three digits represent the country code, followed by the manufacturer’s identification number, the product number, and a check digit.

EAN barcodes offer global compatibility and can be read by barcode scanners worldwide. They enable seamless product identification and tracking, making them an essential tool for international trade and logistics.

Code 128

Code 128 is a versatile barcode symbology that is widely used in various industries for encoding alphanumeric data. It is capable of encoding a wide range of characters, including uppercase letters, numeric digits, and a set of special symbols. Code 128 barcodes start with a start code and end with a stop code, allowing scanners to accurately identify the beginning and end of the barcode. This symbology offers high data density, meaning it can store a large amount of information in a relatively small space. Code 128 barcodes are commonly used for applications such as shipping labels, inventory control, and supply chain management, where detailed and extensive data encoding is required. Its flexibility and ability to encode complex data make it an essential tool for efficient and accurate tracking in various industries.

Choosing the Right Barcode Type

Selecting the most appropriate barcode type for your business depends on various factors, including industry requirements, data capacity, and scanning technology compatibility. Consider the following points when making your decision:

- Application: Determine the specific use case for the barcode, such as inventory management, asset tracking, or product identification.

- Data Capacity: Assess the amount of data you need to encode and ensure that the chosen barcode type can accommodate it.

- Scanning Technology: Consider the scanning devices and software you have or plan to use. Ensure compatibility between your chosen barcode type and scanning equipment.

- Industry Standards: Research industry-specific barcode standards and requirements to ensure compliance and interoperability.

By carefully evaluating these factors, you can make an informed decision and choose the barcode type that best suits your business needs.

Implementing Barcode Labels in Your Business

If you’re considering implementing barcode labels in your business, here are some key steps to follow:

- Identify Your Needs: Assess your business requirements and determine which barcode label system will best suit your operations. Consider factors such as product volume, industry standards, and software compatibility.

- Choose the Right Barcode Label Printer: Invest in a high-quality barcode label printer that meets your specific needs. Ensure compatibility with the barcode symbology you plan to use.

- Design and Print Labels: Utilise barcode label design software to create custom labels. Incorporate relevant product information, such as SKU numbers, product names, and prices.

- Test and Validate: Before implementing barcode labels on a large scale, test the labels and scanning process to ensure accuracy and readability. Make any necessary adjustments to optimize performance.

- Train Staff: Provide comprehensive training to your employees on how to handle barcode labels, operate scanners, and understand the associated software.