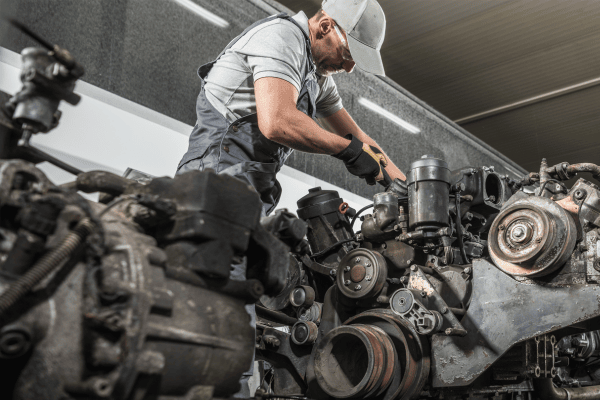

Essential Checklist for Preventive Maintenance of Diesel Trucks

Ensure longevity and reliability with a comprehensive preventive maintenance checklist for diesel trucks

As a diesel truck owner or diesel mechanic, it is crucial to prioritise regular preventive maintenance to ensure the longevity and optimal performance of your vehicle. Implementing a comprehensive maintenance checklist can help identify and address potential issues before they escalate into major problems. This article provides a step-by-step guide to creating and executing an effective preventive maintenance checklist for diesel trucks.

Importance of Preventive Maintenance

Regular maintenance is vital for diesel trucks as it helps prevent unexpected breakdowns, reduces repair costs, and maximises fuel efficiency. By conducting routine inspections and addressing minor issues promptly, you can avoid costly repairs and minimise downtime.

Benefits of Regular Maintenance

Regular preventive maintenance offers several benefits, such as improved safety, enhanced vehicle performance, and increased resale value. It also ensures compliance with regulatory standards and reduces the risk of accidents caused by mechanical failures.

Components of a Preventive Maintenance Checklist

To create a comprehensive preventive maintenance checklist, consider the following key components:

1. Engine

- Checking oil levels and quality

- Inspecting belts and hoses

- Testing battery and charging system

- Cleaning or replacing air filters

- Examining the exhaust system

2. Fuel System

- Inspecting fuel filters

- Checking for fuel leaks

- Testing fuel pressure

- Evaluating the condition of injectors

3. Cooling System

- Checking coolant levels and quality

- Inspecting radiator and hoses

- Testing thermostat and water pump

- Flushing and replacing coolant as needed

4. Electrical System

- Inspecting lighting and signaling systems

- Testing battery terminals and connections

- Checking alternator and starter motor

5. Brake System

- Inspecting brake pads, rotors, and drums

- Checking brake fluid levels

- Testing brake lines and hoses

- Ensuring proper brake function and adjustment

6. Suspension and Steering System

- Checking shock absorbers and struts

- Inspecting ball joints and tie rods

- Testing power steering fluid levels

- Examining steering components for wear

7. Tire Inspection and Maintenance

- Checking tire pressure and tread depth

- Rotating tires as recommended

- Inspecting for cuts, bulges, or uneven wear

- Balancing and aligning tires periodically

8. Fluid Checks and Changes

- Inspecting and topping up fluids (e.g., transmission, power steering, differential)

- Changing engine oil and oil filter regularly

- Flushing and replacing transmission fluid

- Draining and refilling differential fluid

Frequency of Preventive Maintenance

The frequency of preventive maintenance depends on factors such as vehicle usage, operating conditions, and manufacturer recommendations. It is essential to refer to the truck’s manual or consult with a qualified mechanic to determine the appropriate maintenance intervals.

Record – Keeping

Maintaining detailed records of all maintenance activities is crucial for tracking repairs, identifying patterns, and ensuring compliance. Keep a log of inspections, repairs, and parts replacements, including dates, mileage, and costs.

Common Issues to Look Out For

While conducting preventive maintenance, keep an eye out for common issues such as oil leaks, coolant leaks, worn-out belts, and abnormal engine noises. Promptly addressing these problems can prevent more significant damage and avoid costly repairs.

Tagging and Labelling Requirements for Diesel Trucks

Tagging and labelling requirements play a crucial role in ensuring safety, compliance, and effective management of diesel trucks. These requirements help identify key information about the vehicle, its components, and its compliance with regulatory standards.

Here are the key tagging and labelling requirements in relation to diesel trucks:

- Vehicle Identification Number (VIN): Every diesel truck is assigned a unique VIN, which serves as an identification code for the vehicle. The VIN is typically displayed on a metal plate attached to the dashboard or driver’s side door frame. It provides vital information about the truck, including the manufacturer, model year, and production sequence.

- Emission Control Labels: Diesel trucks are subject to emission control regulations to reduce air pollution. These regulations require the installation of emission control systems and the display of emission control labels. These labels provide information about the type of emission control technology used in the vehicle, as well as any specific maintenance or inspection requirements related to the emission control system.

- Hazardous Materials Labels: Diesel trucks that transport hazardous materials must comply with labelling requirements mandated by regulatory agencies. These labels indicate the nature of the hazardous materials being transported, such as flammable, corrosive, or toxic substances. They provide important information to emergency responders and others who may come into contact with the vehicle.

- Weight Rating Labels: Diesel trucks have weight rating labels that indicate the maximum weight the vehicle is designed to carry safely. These labels provide information about the Gross Vehicle Weight Rating (GVWR), which includes the weight of the vehicle, passengers, cargo, and fuel. It is important to adhere to the weight rating limits to ensure safe operation and prevent overloading.

- Tire Labels: Tire labels on diesel trucks provide essential information regarding tire size, load capacity, and recommended tire pressure. These labels also indicate if the tires meet specific standards, such as those set by the Department of Transportation (DOT). Properly inflated and well-maintained tires are crucial for vehicle stability, fuel efficiency, and overall safety.

- Wheel Torque Tags: Wheel torque tags are an essential component of any workshop or garage that deals with changing or rotating wheels. These tags help identify the exact torque required for each wheel, ensuring that the wheels are fastened correctly and safely; they provide information on torque level, initial checks and re-torque intervals.

- Warning Labels: Various warning labels are placed on diesel trucks to alert drivers and passengers about potential hazards and safety precautions. These labels may include warnings about airbags, seatbelt usage, hot surfaces, moving parts, or other specific safety concerns. Compliance with these warning labels helps promote awareness and mitigate potential risks.

- Service and Maintenance Labels: Service and maintenance labels provide guidance on routine maintenance intervals, such as oil changes, filter replacements, or fluid checks. These labels may be placed under the hood, on the engine, or in the owner’s manual. Following the recommended maintenance schedule ensures optimal performance and prolongs the life of the diesel truck.

It is important for diesel truck owners and operators to familiarise themselves with these tagging and labelling requirements. Adhering to these requirements promotes compliance with regulations, enhances safety, and facilitates efficient management of diesel trucks.

Questions about the article? We are here to help!

Our team are experts in choosing suitable asset identification and tracking options for your specific application and environment. We are happy to advise and recommend the most efficient and cost-effective solutions for your workplace.