Ensuring Electrical Safety: Regulations and Standards for Inspections

What you need to know and how to comply with current regulations

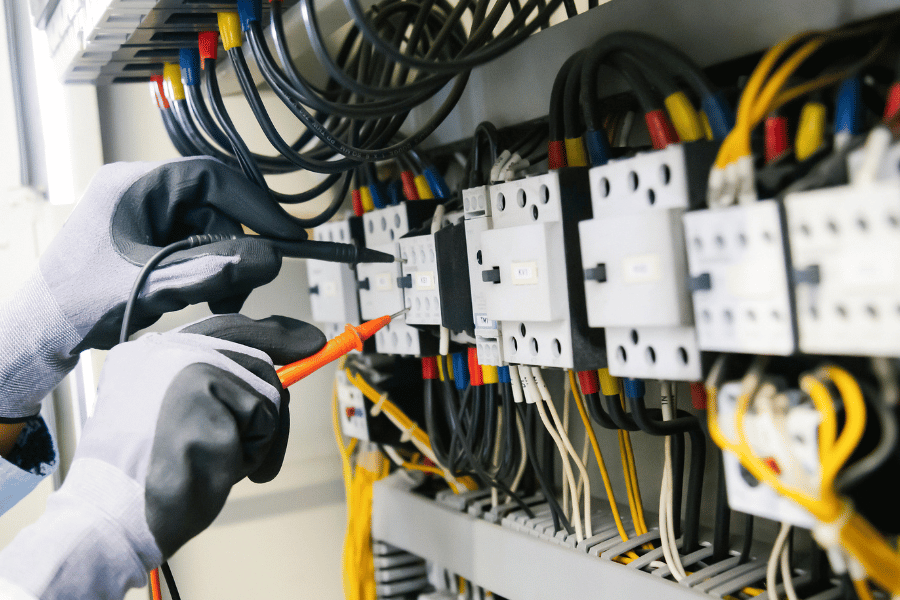

Electricity is an essential part of our daily lives, powering everything from our smartphones to our homes and workplaces. However, it’s important to remember that electricity can be dangerous if not handled correctly. According to the Health and Safety Executive (HSE), electrical accidents account for approximately 25% of all fatal injuries in the workplace. In this blog post, we’ll take a closer look at electrical safety standards in the UK and why it’s crucial to follow safety practices and conduct regular inspections.

Electrical safety standards and codes in the UK

Electrical safety standards in the UK are in place to protect people from electric shock, burns, and other injuries caused by electricity. These standards cover a wide range of areas, from the design and installation of electrical systems to the safe use and maintenance of electrical equipment. The most important electrical safety standards in the UK include the Electricity at Work Regulations 1989, the Wiring Regulations (BS 7671), and the Portable Appliance Testing (PAT) standards.

The importance of electrical safety standards is underscored by the number of injuries and deaths caused by electricity in the UK. According to the HSE, there were 34 fatal electrical accidents in the UK between 2018 and 2019, and over 1,000 non-fatal electrical accidents in the workplace. These accidents can be caused by a range of factors, including faulty electrical equipment, inadequate training, and unsafe working practices.

Regular inspections are crucial

Regular inspections are a critical component of electrical safety. They help identify potential hazards and ensure that electrical systems and equipment are in good working condition. The frequency of inspections depends on the type and use of equipment, but general guidelines recommend annual inspections for commercial and industrial settings and every three to five years for residential settings. Regular inspections also help ensure compliance with electrical safety standards and codes, including proper grounding and bonding, adequate wiring, and appropriate circuit protection.

What are the main regulations about electrical inspections?

In the UK, there are several regulations that require electrical inspections to be conducted on a regular basis. Here are the main regulations related to electrical inspections:

- The Electricity at Work Regulations 1989: This regulation requires that all electrical systems, equipment, and installations are maintained to prevent danger. This includes regular inspections to ensure that they are safe to use.

- The Health and Safety at Work Act 1974: This regulation places a duty on employers to ensure the health and safety of their employees while at work. This includes providing a safe working environment, which requires electrical inspections to be carried out regularly.

- The Management of Health and Safety at Work Regulations 1999: This regulation requires employers to assess and manage the risks associated with their work activities. This includes identifying and controlling risks associated with electrical systems and equipment, which requires regular inspections.

- The Provision and Use of Work Equipment Regulations 1998: This regulation requires that all work equipment, including electrical equipment, is suitable for its intended use and is maintained in a safe condition. This includes regular inspections to ensure that equipment is safe to use.

- The Wiring Regulations (BS 7671): This regulation sets out the requirements for the design, installation, and maintenance of electrical systems in the UK. It requires that electrical installations are inspected and tested at regular intervals to ensure that they are safe to use.

Importance of tagging tested equipment, tools and appliances

Tagging tested equipment, tools, and appliances is an important part of ensuring electrical safety in the UK. By tagging these items with a test label, it indicates that they have been inspected and tested to ensure that they are safe to use. Here are some reasons why tagging tested equipment is crucial:

- Compliance with Regulations: In the UK, there are regulations and standards in place that require electrical equipment, tools, and appliances to be inspected and tested regularly to ensure their safety. By tagging tested equipment, it shows compliance with these regulations.

- Reduced Risk of Accidents: Electrical accidents can be fatal, and tagging tested equipment helps to reduce the risk of accidents. A test label shows that the equipment has been inspected and deemed safe, which can prevent electrical hazards and potential injuries.

- Increased Efficiency: Tagging tested equipment can help to increase efficiency in the workplace. Employees can easily identify which equipment has been tested and is safe to use, which can save time and prevent unnecessary testing of equipment that has already been inspected.

- Liability Protection: By tagging tested equipment, it provides a record of when the equipment was last tested and who tested it. This can be important in the event of an accident, as it shows that the equipment was inspected and deemed safe, which can provide liability protection.

Appliance test tags or PAT testing tags and labels requirements

In the UK, appliance test tags, also known as PAT testing tags, are used to indicate that an electrical appliance has been tested and deemed safe for use. To ensure compliance with regulations and promote electrical safety, there are specific requirements that must be met for appliance test tags. Here are the key requirements for appliance test tags in the UK:

- Test Date: The test tag must include the date that the appliance was tested. This date should be within the recommended interval (usually 1-5 years, depending on the type of equipment) and should indicate when the next test is due.

- Tester Information: The test tag should include the name and contact details of the person or company that carried out the testing.

- Unique Identifier: The appliance test tag must have a unique identifier or code assigned to the equipment, which can be used to track its testing history.

- Test Results: The test tag should include the results of the test, which may include information such as the voltage, current, and resistance of the equipment.

- British Standard: The test tag should display the British Standard number for the relevant testing procedure (e.g. BS 7671 for electrical installations).

- Safety Statement: The test tag should include a statement indicating that the equipment has been tested and is safe to use, such as “Tested for Electrical Safety.”

All of this information should be clearly visible on the test tag or label and should not be obscured by other markings or labels. It is important to note that appliance test tags are not a substitute for regular inspections and maintenance of electrical equipment. Regular inspections and maintenance should still be carried out to ensure that the equipment remains safe to use between tests.

Keeping accurate records of testing and tagging activities is important for ensuring the safety of electrical equipment in the workplace. It also helps to demonstrate compliance with regulatory requirements and can be useful for tracking the maintenance and repair history of the equipment. By complying with electrical safety standards, you can help to prevent injuries and ensure safety in the workplace. Remember, safety always comes first!

Disclaimer: The information provided is intended as a guide and must be read in conjunction with Safety Standards Regulations. Certags strives to provide accurate and credible information, however, you are responsible for checking the relevant standards and safety requirements are accurate for your application and industry.